20MnG Forged thick wall high pressure big diameter steel tube

厚壁高压大口径锻造无缝管20MnG

TE PRESSURE) BOILER AND PETROCHEMICAL INDUSTRY

标准 Standard :

GB3087 —— 中国国家标准 Chinese standard

GB5310 —— 中国国家标准 Chinese standard

ASME SA106 —— 美国锅炉及压力容器规范

ASME SA333 —— 美国锅炉及压力容器规范

ASME SA335 —— 美国锅炉及压力容器规范 Boiler and pressure vessel specification of USA

DIN17175 —— 联邦德国工业标准

EN10216-2 —— 欧洲压力管道标准European standard of pressure pipeline.

用途 Application :

用于低中压锅炉(工作压力一般不大于5.88Mpa,工作温度在450℃以下)的集箱及蒸汽管道;用于高压锅炉(工作压力一般在9.8Mpa以上,工作温度在450℃~650℃之间)的集箱及蒸汽管道,石化工业,核电,军工,海洋工程用管。

Used for steam pipeline of low medium pressure boiler(working pressure is generally not more than 5.88Mpa. Working temperature below 450℃). Used for steam pipeline of high pressure boiler,petrochemical industry ,nuclear power,military industry and ocean engineering etc.(working pressure is generally above 9.8Mpa, working temperature between 450℃~650℃).

主要生产钢管牌号 Main steel grades:

10、20、20G、20MnG、25MnG、15CrMoG、12Cr2MoG、12Cr1MoVG、10Cr9Mo1VNb、SA106B、SA106C、SA333Ⅰ级、SA333Ⅵ级、SA335 P5、SA335 P11、SA335 P12、SA335P22、SA335 P91、SA335 P92、ST45.8/Ⅲ、15Mo3、13CrMo44、10CrMo910、15NiCuMoNb5-6-4 etc.

|

类型 TYPE |

外径OD |

壁厚Wall thickness(S) |

|

|

钢管外径(mm) |

允许偏差(mm) |

钢管壁厚(mm) |

允许偏差(mm) |

长度Length M |

|

热轧管Hot rolled tube |

>219~457 |

±1.0% |

≤20 |

-10%,+12.5% |

6-12.2 |

|

>20~40 |

-10%,+10% |

6-12.2 |

|

>457~1066 |

±0.9% |

>40~70 |

-7%,+9% |

6-12.2 |

|

>70~120 |

-6%,+8% |

6-12.2 |

|

挤压管Hot extruded tube |

200-1320 |

±0.9% |

18-220 |

-6%,+8% |

4-12 |

|

锻造管 Hot forged tube |

140-650 |

±0.9% |

50-250 |

-6%,+8% |

3-19 |

化学成分 Chemical compostion :

|

标准Standard |

牌号 Grade |

化学成分 Chemical composition (%) |

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Cu |

Ni |

V |

Al |

W |

Nb |

N |

|

GB3087 |

10 |

0.07~0.13 |

0.17~0.37 |

0.38~0.65 |

≤0.030 |

≤0.030 |

0.3~0.65 |

/ |

≤0.25 |

≤0.30 |

/ |

/ |

|

|

|

|

20 |

0.17~0.23 |

0.17~0.37 |

0.38~0.65 |

≤0.030 |

≤0.030 |

0.3~0.65 |

/ |

≤0.25 |

≤0.30 |

/ |

/ |

|

|

|

|

GB5310 |

20G |

0.17~0.24 |

0.17~0.37 |

0.35~0.65 |

≤0.030 |

≤0.030 |

≤0.25 |

≤0.15 |

≤0.20 |

≤0.25 |

≤0.08 |

|

|

|

|

|

20MnG |

0.17~0.25 |

0.17~0.37 |

0.70~1.00 |

≤0.030 |

≤0.030 |

≤0.25 |

≤0.15 |

≤0.20 |

≤0.25 |

≤0.08 |

|

|

|

|

|

25MnG |

0.23~0.27 |

0.17~0.37 |

0.70~1.00 |

≤0.030 |

≤0.030 |

≤0.25 |

≤0.15 |

≤0.20 |

≤0.25 |

≤0.08 |

|

|

|

|

|

15CrMo |

0.12~0.18 |

0.17~0.37 |

0.40~0.70 |

≤0.030 |

≤0.030 |

0.80~1.10 |

0.40~0.55 |

≤0.20 |

≤0.30 |

|

|

|

|

|

|

12Cr2MoG |

0.08~0.15 |

≤0.50 |

0.40~0.70 |

≤0.030 |

≤0.030 |

2.00~2.50 |

0.90~1.20 |

≤0.20 |

≤0.30 |

|

|

|

|

|

|

12Cr1MoV |

0.08~0.15 |

0.17~0.37 |

0.40~0.70 |

≤0.030 |

≤0.030 |

0.90~1.20 |

0.25~0.35 |

≤0.20 |

≤0.30 |

0.15~0.30 |

|

|

|

|

|

10Cr9Mo1VNb |

0.08~0.12 |

0.20~0.50 |

0.30~0.60 |

≤0.020 |

≤0.010 |

8.00~9.50 |

0.85~1.05 |

≤0.20 |

≤0.40 |

0.18~0.25 |

≤0.015 |

|

0.06~0.10 |

0.03~0.07 |

|

ASME SA106 |

SA106B |

0.17~0.25 |

≥0.1 |

0.70~1.00 |

≤0.030 |

≤0.030 |

|

|

|

|

|

|

|

|

|

|

ASME SA106 |

SA106C |

0.23~0.27 |

≥0.1 |

0.70~1.00 |

≤0.030 |

≤0.030 |

|

|

|

|

|

|

|

|

|

|

ASME SA333 |

SA333Ⅰ级 |

0.09~0.12 |

/ |

0.7~1.00 |

≤0.020 |

≤0.010 |

|

|

|

|

|

|

|

|

|

|

SA333Ⅵ级 |

0.09~0.12 |

≥0.1 |

0.9~1.10 |

≤0.020 |

≤0.010 |

|

|

|

|

|

|

|

|

|

|

ASME SA335 |

SA335 P11 |

0.05~0.15 |

0.50~1.0 |

0.30~0.60 |

≤0.030 |

≤0.030 |

1.00~1.50 |

0.50~1.00 |

|

|

|

|

|

|

|

|

|

SA335 P12 |

0.05~0.15 |

≤0.50 |

0.30~0.61 |

≤0.030 |

≤0.030 |

0.80~1.25 |

0.44~0.65 |

|

|

|

|

|

|

|

|

|

SA335 P22 |

0.05~0.15 |

≤0.50 |

0.30~0.60 |

≤0.030 |

≤0.030 |

1.90~2.60 |

0.87~1.13 |

|

|

|

|

|

|

|

|

|

SA335 P5 |

≤0.15 |

≤0.50 |

0.30~0.60 |

≤0.030 |

≤0.030 |

4.00/6.00 |

0.45/0.65 |

|

|

|

|

|

|

|

|

|

SA335 P91 |

0.08~0.12 |

0.20~0.50 |

0.30~0.60 |

≤0.020 |

≤0.010 |

8.00~9.50 |

0.85~1.05 |

|

≤0.40 |

0.18~0.25 |

≤0.015 |

|

0.06~0.10 |

0.03~0.07 |

|

|

SA335 P92 |

0.07~0.13 |

≤0.50 |

0.30~0.60 |

≤0.020 |

≤0.010 |

8.50~9.50 |

0.30~0.60 |

0.30~0.60 |

≤0.40 |

0.15~0.25 |

≤0.015 |

1.50~2.00 |

0.04~0.09 |

0.03~0.07 |

|

|

|

DIN 17175 |

ST45.8/Ⅲ |

≤0.21 |

0.10~0.35 |

0.40~1.20 |

≤0.040 |

≤0.040 |

≤0.30 |

|

|

|

|

|

|

|

|

|

15Mo3 |

0.12~0.20 |

0.10~0.35 |

0.40~0.80 |

≤0.035 |

≤0.035 |

|

0.25~0.35 |

|

|

|

|

|

|

|

|

13CrMo44 |

0.10~0.18 |

0.10~0.35 |

0.40~0.70 |

≤0.035 |

≤0.035 |

0.70~1.10 |

0.45~0.65 |

|

|

|

|

|

|

|

|

10CrMo910 |

0.08~0.15 |

≤0.50 |

0.30~0.70 |

≤0.025 |

≤0.020 |

2.00~2.50 |

0.90~1.10 |

≤0.30 |

≤0.30 |

|

≤0.015 |

|

|

|

力学性能 Mechanical propeties:

|

标准Standard |

牌号 Grade |

抗拉强度Tensile(MPa) |

屈服强度 Yeild(MPa) |

伸长率 Elongation (%) |

冲击功 Impact (J) |

硬度 Hardness |

|

GB3087 |

10 |

335~475 |

≥195 |

≥24 |

|

/ |

|

20 |

410~550 |

≥245 |

≥20 |

|

/ |

|

GB5310 |

20G |

410~550 |

≥245 |

≥24 |

≥35 |

/ |

|

20MnG |

≥415 |

≥240 |

≥22 |

≥35 |

/ |

|

25MnG |

≥485 |

≥275 |

≥20 |

≥35 |

/ |

|

15CrMoG |

440~640 |

≥235 |

≥21 |

≥35 |

/ |

|

12Cr2MoG |

450~600 |

≥280 |

≥20 |

≥35 |

/ |

|

12Cr1MoVG |

470~640 |

≥255 |

≥21 |

≥35 |

/ |

|

10Cr9Mo1VNb |

≥585 |

≥415 |

≥20 |

≥35 |

/ |

|

ASME SA106 |

SA106B |

≥415 |

≥240 |

≥22 |

≥35 |

/ |

|

SA106C |

≥485 |

≥275 |

≥20 |

≥35 |

/ |

|

ASME SA333 |

SA333Ⅰ级 |

≥380 |

≥205 |

≥28 |

-45≥18 |

/ |

|

ASME SA335 |

SA335 P11 |

≥415 |

≥205 |

≥22 |

≥35 |

|

|

|

SA335 P12 |

≥415 |

≥220 |

≥22 |

≥35 |

≤163HB |

|

|

SA335 P22 |

≥415 |

≥205 |

≥22 |

≥35 |

≤163HB |

|

|

SA335 P5 |

≥415 |

≥205 |

≥22 |

≥35 |

≤187HB |

|

|

SA335 P91 |

585~760 |

≥415 |

≥20 |

≥35 |

≤250HB |

|

|

SA335 P92 |

≥620 |

≥440 |

≥20 |

≥35 |

250HB |

|

DIN17175 |

ST45.8/Ⅲ |

410~530 |

≥255 |

≥21 |

≥27(DVM) |

/ |

|

15Mo3 |

450~600 |

≥270 |

≥22 |

≥34(DVM) |

/ |

|

13CrMo44 |

440~590 |

≥290 |

≥22 |

≥34(DVM) |

/ |

|

10CrMo910 |

480~630 |

≥280 |

≥20 |

≥34(DVM) |

/ |

|

EN10216-2 |

15NiCuMoNb5-6-4 (WB36) |

610~780 |

≥440 |

≥19 |

≥40 |

/ |

|

|

A312TP304 |

≥515 |

≥205 |

35 |

|

|

|

|

A312TP316 |

≥515 |

≥205 |

35 |

|

|

|

|

21CrMo10 |

≥515 |

≥205 |

35 |

|

|

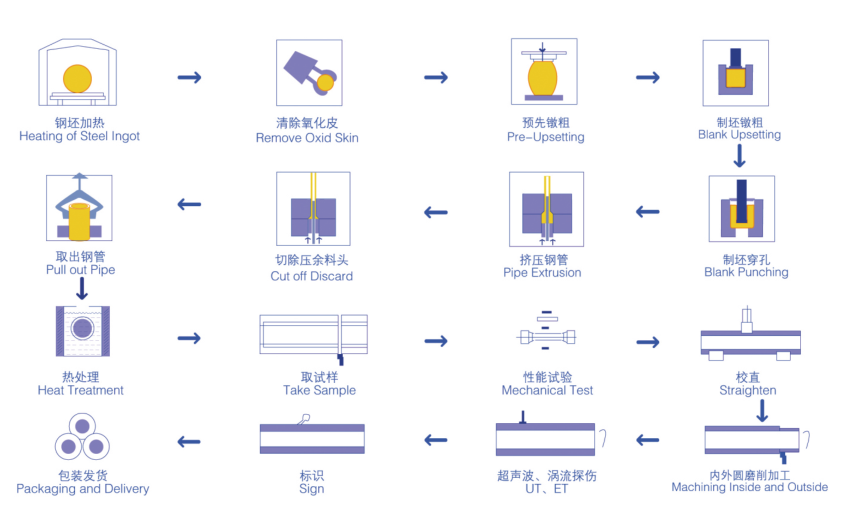

生产工艺流程 producing process flow :

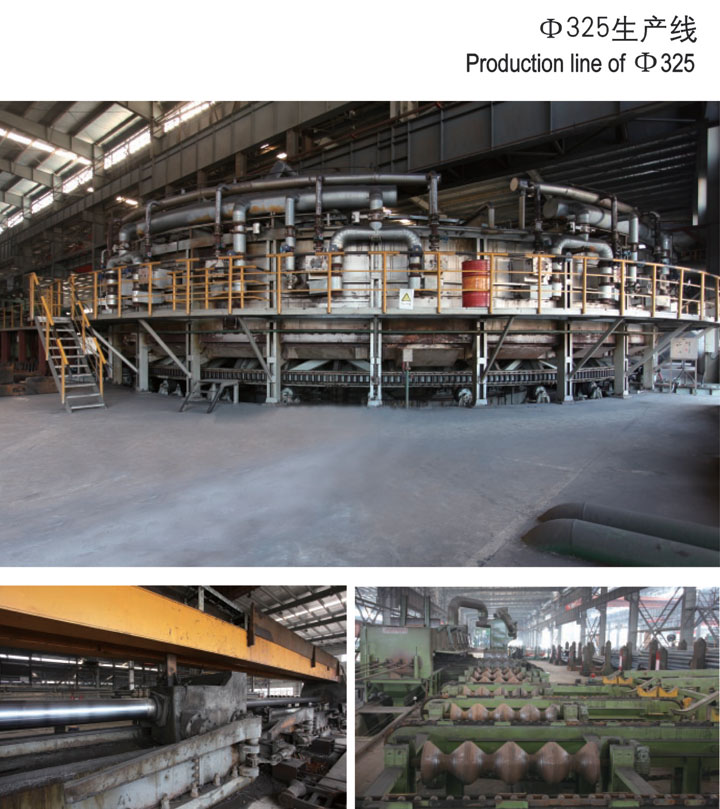

设备EQUIPMENTS:

应用领域 application fields: